English

English

Turnover time: 2025/01/16 / Access number: 55

Brand: TENCAN

Applications: Instructions of Model No. Of Glove Box With Purification System Quantity of Gloves: 2, 3, 4, 6, 8 gloves are available.S/D: D indicates double-side operation,S indicates single operation800: 800 indi

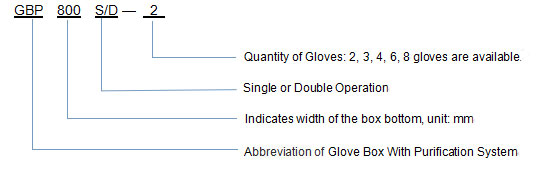

Instructions of Model No. Of Glove Box With Purification System

Quantity of Gloves: 2, 3, 4, 6, 8 gloves are available.

S/D: D indicates double-side operation,S indicates single operation

800: 800 indicates width of the box bottom, unit: mm

GBP: GBP is abbreviation of Glove Box With Purification System

| Specifications of Standard Model of Purification Glove Box | ||||||

| No. | Model No. | Box Dimensions | Total Dimensions | Operating Sides | Numbers of Gloves | Options |

| 1 | GBP800S-2 | 1200*800*930mm | 1915*830*1830mm | Single | 2 | Single or double purification columns |

| 2 | GBP1000S-4 | 1200*1000*930mm | 1915*1060*1830mm | Single | 4 | Single or double purification columns |

| 3 | GBP1000D-4 | 1200*1000*930mm | 1915*1060*1830mm | Double | 4 | Single or double purification columns |

| 4 | GBP1200S-2 | 1200*1200*930mm | 1915*1260*1830mm | Single | 2 | Single or double purification columns |

| 5 | GBP1200D-4 | 1200*1200*930mm | 1915*1260*1830mm | Double | 4 | Single or double purification columns |

| 6 | GBP800S-3 | 1500*800*930mm | 2215*1060*1830mm | Single | 3 | Single or double purification columns |

| 7 | GBP1000S-3 | 1500*1000*930mm | 2215*1060*1830mm | Single | 3 | Single or double purification columns |

| 8 | GBP1000D-6 | 1500*1000*930mm | 2215*1060*1830mm | Double | 6 | Single or double purification columns |

| 9 | GBP1200S-3 | 1500*1200*930mm | 2215*1260*1830mm | Single | 3 | Single or double purification columns |

| 10 | GBP1200D-6 | 1500*1200*930mm | 2215*1260*1830mm | Double | 6 | Single or double purification columns |

| 11 | GBP800S-4 | 1900*800*930mm | 2615*1060*1830mm | Single | 4 | Single or double purification columns |

| 12 | GBP1000S-4 | 1900*1000*930mm | 2615*1060*1830mm | Single | 4 | Single or double purification columns |

| 13 | GBP1000D-8 | 1900*1000*930mm | 2615*1060*1830mm | Double | 8 | Single or double purification columns |

| 14 | GBP1200S-4 | 1900*1200*930mm | 2615*1260*1830mm | Single | 4 | Single or double purification columns |

| 15 | GBP1200D-8 | 1900*1200*930mm | 2615*1260*1830mm | Double | 8 | Single or double purification columns |

| Notes: Cabinet water and oxygen content under the standard condition: Water content ≤1ppm, oxygen content≤1 ppm (Note: Standard condition is that an atmospheric pressure, constant temperature of 20 degree). Leakage Rate: ≤0.05Vol%/ h (subject to change value of oxygen content in box) Used Gases a) Working Gas: N2、Ar、He and etc. b) Controlling Gas: Compressed air or Inert Gas. C) Restoring Gas: Mixed gas of working gas and hydrogen. Restoring gas is as same as working gas if there is only water removal system or oxygen removal system. Remarks: All Single side boxes of 4 gloves are assembled glove box. Numbers of assembled box can be ordered as per customer’s needs. Quantity of purification columns is also designed to be matched according to customer’s requirements |

Connected

with a variety of sealed containers, equipment and production lines to

form a closed circulation environment ,the internal purification

materials of the purification column does purification treatment with

inert gas ( mainly water, oxygen elimination) enabling the system to

always keep high clean and high purity inert gas environment.

The working gas of the system is inert gas or nitrogen. The control gas

of the system is compressed air or inert gas or nitrogen. The restoring

gas for the system is inert gas or mixture of inert gas and hydrogen.

THE STRUCTURE OF THE GAS PURIFICATION SYSTEM

The gas purification system is with excellent sealing performance which

is the key to guarantee the equipment performance and security. For this

TENCAN is always being scrupulous about every detail. The main material

of the system is made of corrosion resistant stainless steel and alloy

material, the structure is treated by plastic spraying, color is light.

The system structure and components are all of standardized design,

realization of disassembly namely replacement namely.

THE BASIC FUNCTIONS OF THE GAS PURIFICATION SYSTEM

| NAME | INTRODUCTION |

| Automatic control | Realize the automatic controlling and monitoring of the equipment operation by program control unit |

| Manual/automatic gas replacement within the box | Before first using the system, “replace” the air of the box body with inert gas or nitrogen. Gas replacement can be achieved easily by using automatic box gas replacement function system provides |

| Manual/automatic gas replacement within the chamber | Gas replacement within the chamber is required when the material enter the box. Gas replacement can be achieved easily by using automatic chamber gas replacement function system provides |

| Gas purification control | Set the system purification be automatic after setting the required working status and outcome, then system will automatically keep the atmosphere of the box, therefore the system can finish the work in no case of personal; also we can choose manual control. |

| Gas pressure control | After setting the gas pressure range and choosing automatic pressure control, the system will maintain the desired gas pressure automatically for us, also we can choose manual control. |

| Foot-pedal air pressure control | Use the foot-pedal controller--controlling the gas pressure of the system through inflation and deflation. |

| Restoring the purification system | Restoring of purification materials is completed by the system automatically, and we only need to provide the system restore conditions, then the system can automatically complete the restoring work for us after opening restoring, and the whole process does not need staff to monitor. |

| Online condition examination | The user can use the work state examination function of the equipment unit the control system provides to observe components working condition, and check out the fault source of various functions and components. |

| System parameter setting | With a system setting function, the user can set various parameters of the system to achieve desired working conditions and function set |

| Data recording function | We can trace back or monitor the production or experiment through operating parameters recording of the equipment the system provides. |

| Controlling gas reserving function | The reserved control gas will guarantee the equipment to continue working in a long time when the control gas source is temporarily cut off or insufficient control air is supplied. |

| Circulating gas cooling standby function | A heat exchanger for cooling the circulating gas provided within the purification system, can enter individually the coolant controlling the circulating gas temperature. |

| Multilevel security system | The control system sets up multi-level function of safety tips, alarm and forbidden to ensure the safety of personnel and equipment. |

| Protection function from blocking purification circulation | When the circulating system is blocked, the control system will indicate alarm, and actively adjust the circulation velocity to protect the motor, and can also through the function check out the system’s issues that the circulates suffocated, conduit not free, filter dust collection and other issues. |

OPTIONAL FUNCTION OF THE GAS PURIFICATION SYSTEM

Data recording and printing Remote service functions

THE BASIC ACCESSORIES OF THE GAS PURIFICATION SYSTEM

| Water sensor | Range 0-1000ppm,used for measuring the numerical value of water content within the box, Touch screen displaying, imported brand. |

| Oxygen sensor | Range 0-1000ppm,used for measuring the numerical value of oxygen content within the box, Touch screen displaying, imported brand. |

| Organic solvent absorber | Volume 21L,used for absorbing the solvent gas generated in the process of using the glove box to protect purification material within the system. |

THE OPTIONAL CONFIGURATION OF THE GAS PURIFICATION SYSTEM

| Water sensor | Range 0-1000ppm,used for measuring the numerical value of water content within the box, Touch screen displaying, imported brand. |

| Oxygen sensor | Range 0-1000ppm,used for measuring the numerical value of oxygen content within the box, Touch screen displaying, imported brand. |

| Organic solvent absorber | Volume 21L,used for absorbing the solvent gas generated in the process of using the glove box to protect purification material within the system. |

GP25 SERIES “THE PURIFICATION VOLUME 25L”

| MODEL | REMARKS | BOX SIZE(mm) | Remarks |

| GP25S | Single purification system | 800*600*820 | With the function of both water and oxygen elimination or of only water elimination or only oxygen elimination. Introduction of renewable/reducible purification system |

| GP25D | Double purification column | 900*650*820 |

POWER SUPPLY: 220V(AC) 50HZ MAXIMUM POWER: 3000W